Enhance Your Service Workflow With Reliable Industrial Scales

In today's competitive landscape, the precision of commercial scales plays a critical duty in enhancing general business operations. As services look for to enhance efficiency, comprehending the different kinds of scales and their technical improvements ends up being necessary.

Significance of Accurate Considering

Precise considering is essential in different industrial applications, as also minor inconsistencies can bring about substantial operational inadequacies and monetary losses. Industries such as manufacturing, logistics, and food processing rely on exact measurements to make sure item quality, regulative conformity, and optimum source management. Incorrect weights can result in overflow, waste of resources, or insufficient supply, affecting success and consumer fulfillment.

Additionally, accurate weighing is important for safety and security and ecological conformity. In the chemical market, incorrect measurements can lead to improper blends, resulting in harmful circumstances or legal implications. Additionally, in the food industry, accurate considering is vital for adhering to nutritional labeling needs, making sure that consumers receive precise details relating to the products they purchase.

The integration of trustworthy industrial scales not only enhances operational efficiency but also sustains data-driven decision-making. Investing in high-grade industrial evaluating options is important for services intending to keep an affordable edge in today's dynamic industry.

Kinds of Industrial Scales

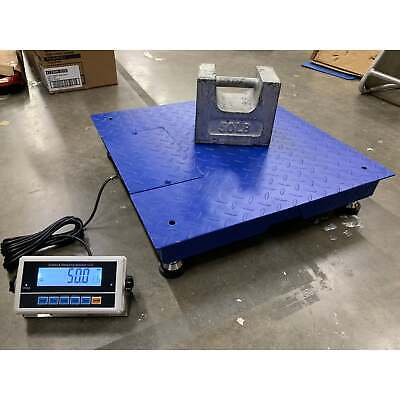

Industrial ranges are available in numerous types, each designed to fulfill certain evaluating needs across different industries. Amongst one of the most usual kinds are system scales, which provide a huge evaluating surface ideal for heavy things, making them excellent for warehouses and making facilities. These ranges typically include digital display screens for simple reading.

An additional type is bench scales, which are usually smaller and mobile, ideal for usage in research laboratories or retail environments. They permit quick measurement of smaller sized things while maintaining accuracy. For applications requiring the evaluating of fluids, tank scales are particularly developed to gauge the weight of tank, guaranteeing precise stock administration.

Furthermore, flooring scales are made use of for evaluating heavy tons on the ground degree, frequently utilized in shipping and getting divisions. Crane scales are likewise noteworthy; they are put on hold from a structure to consider hefty products in commercial settings. Ultimately, lots cells play an essential duty in several ranges, converting push into an electric signal for accurate weight measurement. Each kind of commercial range serves a distinct objective, improving operational effectiveness across varied markets.

Benefits of Modern Modern Technology

Additionally, modern commercial ranges commonly come outfitted with connection features that allow smooth integration with various other systems, such as stock administration and manufacturing monitoring. This interconnectivity fosters an extra natural operations and lessens downtime, as services can keep an eye on performance metrics and make data-driven choices quickly.

In addition, several modern ranges offer personalized setups and user-friendly interfaces, permitting drivers to adjust their tools for specific operational needs. Improved durability and resilience against severe environmental conditions better add to the long life and dependability of contemporary scales, guaranteeing they can stand up to the rigors of industrial usage.

Picking the Right Tools

Various industries might call for distinctive kinds of scales, such as floor ranges for hefty tons, bench ranges for smaller sized things, or mobile ranges for flexibility. Furthermore, taking into consideration the environment in which the ranges will be used is essential. For example, tools used in severe settings may need to be immune and tough to dirt, wetness, or severe temperatures.

Another critical variable is the technology used in the ranges. Digital scales often offer boosted accuracy and simplicity of usage, while analog scales may be enough for much less demanding applications. It is vital to review the scalability of the equipment, guaranteeing that it can accommodate future development or adjustments in production processes.

Lastly, services must consider the credibility and integrity of manufacturers, as buying top quality tools can result in long-term expense savings and boosted functional efficiency.

Maintenance for Durability

Regular maintenance is vital for guaranteeing the longevity and optimum performance of industrial scales. An organized method to upkeep not just expands the life of the tools yet likewise ensures precise measurements critical for operational performance.

Begin with routine assessments to determine deterioration, making certain components such as lots cells and displays function appropriately. Calibration checks must be carried out regularly, preferably after substantial modifications in ecological problems or complying with hefty use. Exact calibration is important for conformity with Homepage industry requirements and for maintaining the integrity of weight measurements.

Cleaning up is another vital element of maintenance. Dirt, debris, and destructive materials can impair efficiency and bring about mistakes. Use suitable cleansing agents and strategies his comment is here to protect delicate components. In addition, it is a good idea to develop a maintenance schedule that videotapes each solution check out, calibration, and any kind of fixings done. This documents help in tracking equipment efficiency and preparation for future upkeep needs.

Finally, educating personnel on correct usage and treatment techniques will certainly reduce the possibility of operator error, even more improving range reliability. By prioritizing normal maintenance, businesses can make certain that their industrial ranges stay a trustworthy property in their procedures.

Verdict

In summary, the assimilation of reputable commercial ranges is vital for improving organization operations across various sectors. Accurate considering not only minimizes inconsistencies however additionally optimizes supply monitoring and makes sure conformity with sector criteria. The selection of ideal equipment, coupled with contemporary technical developments, can substantially boost efficiency and minimize functional expenses. Normal upkeep and training more add to the durability and accuracy of these ranges, fostering data-driven decision-making and eventually sustaining general service success.

Industrial scales come in numerous types, each created to satisfy specific evaluating needs across different markets. Crane scales are also significant; they are suspended from a structure to weigh hefty materials in industrial setups.Different markets may need distinctive kinds of ranges, such as floor ranges for heavy lots, bench ranges for smaller Continue sized products, or portable ranges for adaptability - Industrial Scales. Digital scales typically provide boosted precision and convenience of use, while analog scales might be adequate for less requiring applications.In recap, the integration of trustworthy industrial ranges is vital for improving organization operations throughout different industries